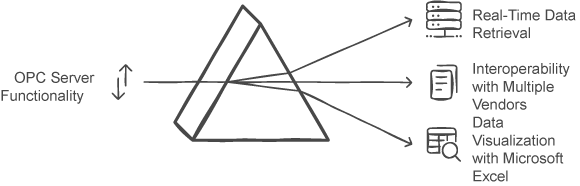

Connecting Two OPC Servers: From OPC DA Server to OPC UA ServerWhat is an OPC Server and OPC Client?OPC server is a software application designed to facilitate data exchange between industrial devices like PLCs, DCS, and HMI systems. It acts as a bridge between OPC clients and a hardware device, allowing them to share data efficiently. When an OPC client, such as an SCADA or custom dashboard, requests data, the OPC server queries the PLC or other device, processes the response, and returns the requested information in readable form to the requestor. The OPC Data Manager handles the necessary protocols and formats, ensuring secure and reliable communication.

What is the role of an OPC Server?In a typical industrial setup, an OPC server connects to a controller or programmable logic controllers to retrieve real-time data and return requested data to an SCADA system or your custom application. The flexibility of the standard allows developers to build one application that can work with multiple servers from various vendors, enhancing overall reliability. Additionally, users could also use tools like Microsoft Excel to visualize and analyze data retrieved from the OPC server, making it a powerful option for data management in industrial environments.

How does the OPC UA Server differ from OPC DA?OPC UA (Unified Architecture) and OPC Data Access (DA) serve different purposes in industrial automation. While OPC DA primarily focuses on real-time data access, using OLE (Object Linking and Embedding) technology on Windows. OPC UA provides a more robust and flexible interface that can support different types of data. This means that while OPC DA operates mainly on a single computer, OPC UA can talk to another OPC server over networks using TCP, enhancing its scalability and interoperability. Unified Architecture also allows manufacturers to integrate historical data access (HDA) and alarm and events (AE) to their servers. Get Started with Datatag Link Setup

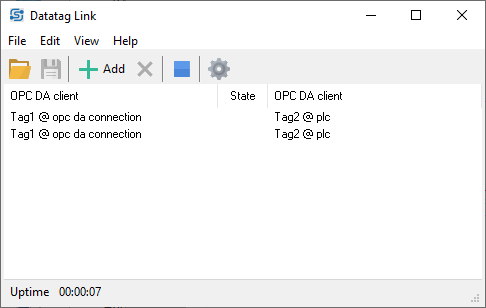

Why you may need to transfer OPC data between servers?The main purpose of OPC is to connect two OPC-enabled devices, controllers, or PLCs that can't talk to each other directly, but they control one process. This connection lets the devices talk and share data easily, making the control system work better together. Using an intermediary layer, such as OPC, data from one device can be translated and sent to the other device of other vendors using a different base communication protocol. Connecting OPC-enabled devices resolves communication barriers and enhances system functionality, flexibility, and scalability, thus driving efficiency and productivity in industrial processes. How to Make a Bridge Between OPC Servers?It is not possible for one OPC server to be directly connected to another server. It is responsible for serving requests from a client application. When you need to integrate servers with different OPC standards (UA and DA), the problem becomes even more difficult. This issue arises because OPC DA (Data Access) and OPC UA (Unified Architecture) have quite unfamiliar ways of communicating. One common solution is to implement a gateway or middleware that can translate requests and data between the two standards. This gateway functions as an OPC client, establishes a connection to both servers and initiates periodic polling for new data, which is subsequently transferred to another endpoint. Apart of OPC Data Logger, this link both in both directions for all configured OPC tags. What tool can be used for data transfer between OPC servers?Datatag Link software is a middleware utility for all modern Windows operating systems. It provides the required features for industrial applications and process control.

Get Started with Datatag Link Setup

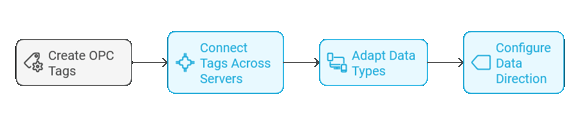

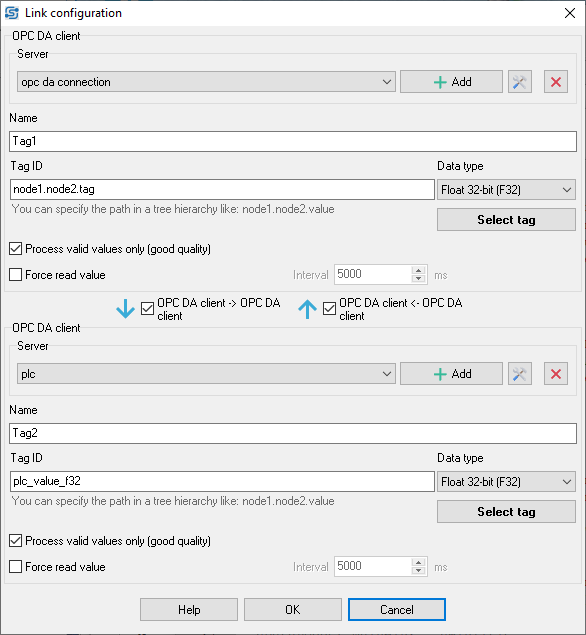

How to configure an OPC gateway for interoperability?The Datatag Link tool helps connect OPC tags from one server to tags on a different server. The names of these tags could be different. You create tags by yourself. In real-time, the program can also adopt data types of values (e.g., float numbers to decimal numbers, 16-bit decimal numbers to 32-bit signed decimals). You can also configure data direction for every OPC tag.

Common Challenges When Connecting Two OPC ServersWhat are typical issues faced with OPC server connectivity?Should you establish a connection with an OPC DA server, it is advisable to install our software directly on the machine hosting the OPC DA server. This approach will eliminate a potential vulnerability within the data transmission pathway.

Consider the OPC UA security schema if you connect to the OPC UA server on the other side. The strongest security may add significant overheads to data packets that increase delays or PLC's CPU load. What are the limitations of using DCOM with OPC DA?

Connecting Two OPC Servers: From OPC DA Server to OPC UA Server. Datatag Link related topics:hereData Logger Suite | Logger for OPC DA UA HDA AE | Connect OPC servers | OPC Tags Grouping |

|