Why Connect Two MODBUS Slave Devices?

Linking two MODBUS slave devices might sound like a niche task, but in the world of industrial automation, it's a typical usage in some areas. Whether you're syncing data across systems or automating workflows, connecting MODBUS slaves can streamline operations and keep everything running like a well-oiled machine. Here's why you might want to give it a shot:

- Data synchronization: Keep your data consistent across devices. No more mismatched numbers or outdated info - everything stays in sync.

- Process automation: Let your devices talk to each other and trigger actions automatically. It's like having a conversation between machines that keeps your processes humming.

- Integration with other systems: Want to tie your MODBUS devices into a SCADA system or a central database? Linking them makes it a breeze to integrate with other platforms.

In short, connecting MODBUS slaves isn't just a technical exercise - it's a productivity booster.

Get Started with Datatag Link Setup

How It Works

So, how does Datatag Link make this magic happen? It's all about real-time communication and smart data handling. Here's the breakdown:

- MODBUS communication: Datatag Link uses the MODBUS protocol (RTU or TCP) to chat with each slave device. It grabs data from one device and sends it to the other, and vice versa. It's like a postal service for your industrial data.

- Tag linking: By creating a tag link between the two devices, Datatag Link ensures that any change in one device's data is instantly mirrored in the other. This is perfect for keeping systems in sync without lifting a finger.

- Real-time logging: Every data transaction is logged in real time, so you can keep tabs on what's happening. If something goes sideways, you've got a paper trail to help you figure it out.

- Flexible configuration: Datatag Link supports two-way communication, so data can flow in both directions. You can also configure polling intervals, memory addresses, and data types to fit your specific needs. It's like having a custom-tailored suit for your data.

Step-by-Step Tutorial: Connecting Two MODBUS Slave Devices with Datatag Link

Ready to get your hands dirty? This tutorial will walk you through connecting two MODBUS slave devices using Datatag Link. By the end, you'll have a seamless data exchange setup that'll make your life a whole lot easier.

Download Datatag Link Now

Step 1: Install and launch Datatag Link

- Download and install: If you haven't already, download Datatag Link from our website. During installation, pick the connectors you need on both sides - think of it as choosing the right tools for the job.

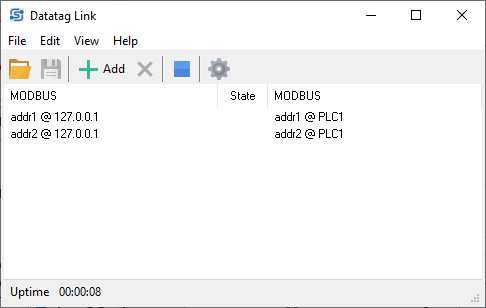

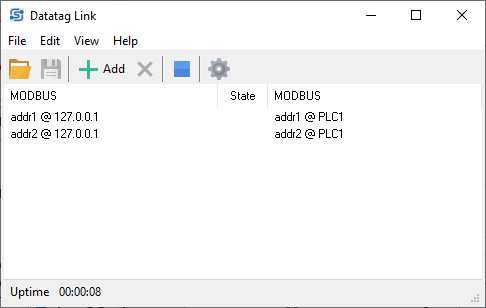

- Launch the trogram: Once installed, fire up Datatag Link. You'll see the main window with a Tag List, Toolbar, and Status Panel. It's your command center for all things where you can add or edit links for your MODBUS slaves.

Step 2: Configure the first MODBUS slave connection

1. Add a new connection:

- Click the Add button on the toolbar to start a new tag link.

- Click Add under the Connection section to set up your first MODBUS slave device.

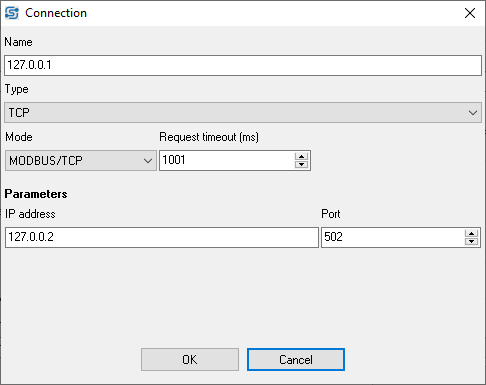

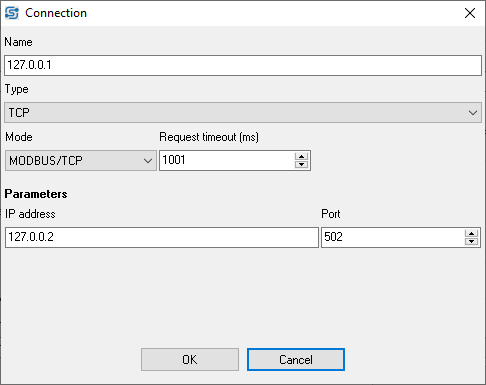

2. Set connection parameters:

- Name: Give your connection a name that makes sense, like "MODBUS Slave 1."

- Type: Choose between MODBUS RTU or MODBUS TCP, depending on how your device connects.

- Device Address: Enter the address of your MODBUS slave device (e.g., 1).

- Click OK to save the connection settings.

- The new connection will pop up in the Connection list. You can reuse this connection for other links if needed.

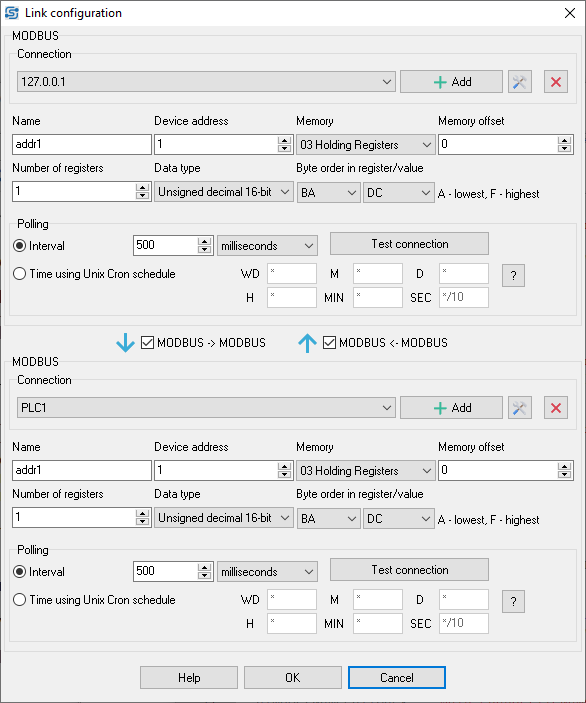

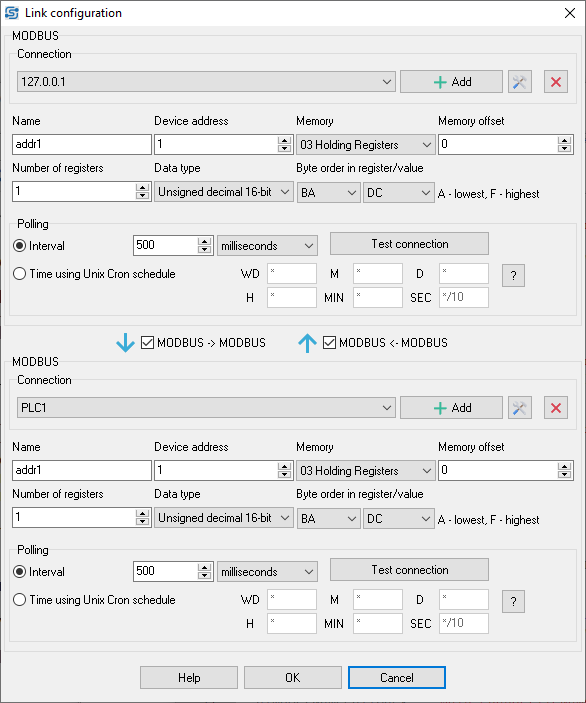

- Select tag parameters:

- Memory area: Pick the memory area you want to work with, like Holding Registers.

- Memory offset: Enter the offset for the register you're targeting (e.g., 0).

- Data type: Specify the data type, such as Integer.

- Polling interval: Set how often you want to poll data from the device (e.g., every 1000 ms).

Step 3: Configure the second MODBUS slave connection

1. Configure connection on another side:

- Repeat the steps from Step 2 to set up the second MODBUS slave device on the other side of your link.

- Make sure the Device Address, Memory Area, and Memory Offset are different from the first device.

- Transmission Direction: Set this to Bidirectional if you want data to flow both ways.

2. Save the configuration:

- Click the OK button to save the second connection.

- The new connection will appear in the Tag List.

- Both MODBUS slave devices should now be listed in two columns.

3. Verify the connection:

- Check the Status Panel for symbols like "<" or ">" to confirm data is moving between the devices.

Step 5: Save and test the configuration

1. Save the configuration:

- Go to File → Save or click the Save button on the toolbar to save your setup. This ensures your settings are ready to roll the next time you start the program.

2. Test the connection:

- Keep an eye on the Status Panel for any errors or warnings.

- Use the Transactions File option under the View Menu to check the data exchange logs.

- Use 3rd party tools to check data on both side. For example our Serial Port Monitor software with the MODBUS plugin.

Conclusion

And there you have it! You've successfully connected two MODBUS slave devices using Datatag Link. This setup lets your devices share data seamlessly, making your automation tasks a whole lot smoother. For more advanced tweaks, dive into the Program Settings and Advanced Options in the software.

For more detailed instructions, check out the full Datatag Link Manual.

Explore Advanced Features

FAQ

Q1: Can I connect more than two MODBUS slave devices using Datatag Link?

A: Sure! Datatag Link supports up to 65K tags, so you can link as many MODBUS slave devices as you need. Just configure each device individually and create tag links between them.

Q2: What if my MODBUS devices use different data types?

A: No worries - Datatag Link handles data type conversion automatically. If the data types don't match, the software will try to convert them. You can also manually set the data type for each tag if you want more control.

Q3: How do I troubleshoot connection issues with MODBUS devices?

A: If you hit a snag, here's what to do:

- Check the Message Log under the File Menu for error messages.

- Double-check the Device Address, Memory Area, and Memory Offset settings for each device.

- Make sure the MODBUS protocol (RTU or TCP) and connection parameters (like baud rate or IP address) match your device specs.

- Use the Test Connection feature to confirm Datatag Link can talk to each device.

Connecting Two OPC Servers: From OPC DA Server to OPC UA Server.

OPC Tag Grouping From Different OPC DA Servers To OPC UA.

Connecting an OPC Client/Server to an SQL Database Using Datatag Link.

Connecting an OPC Client to an MQTT Broker In Real-Time.

Linking Tags In Two MODBUS Slave Devices In Real-Time.

How to Connect a MODBUS Slave Device to an SQL Database.

Log OPC DA, UA, HDA, AE data to SQL or Excel.

Data Logger Suite - log data from various data sources (OPC, MQTT, MODBUS, SNMP, etc.).